About S.C.F. ENGINEERING

Our History

Founded over 30 years ago, S.C.F. ENGINEERING s.r.l. has established a strong reputation for excellence in consulting services, focusing on innovative solutions in chip removal machining.

Our Mission

We aim to enhance our clients' manufacturing processes through high-quality consulting services, becoming a trusted partner that adapts to their evolving needs and challenges.

Our Values

We are committed to quality, integrity, and continuous improvement. Our collaborative approach ensures that we build lasting partnerships with clients and suppliers, driving innovation and success.

Our Specialized Services for Precision Engineering

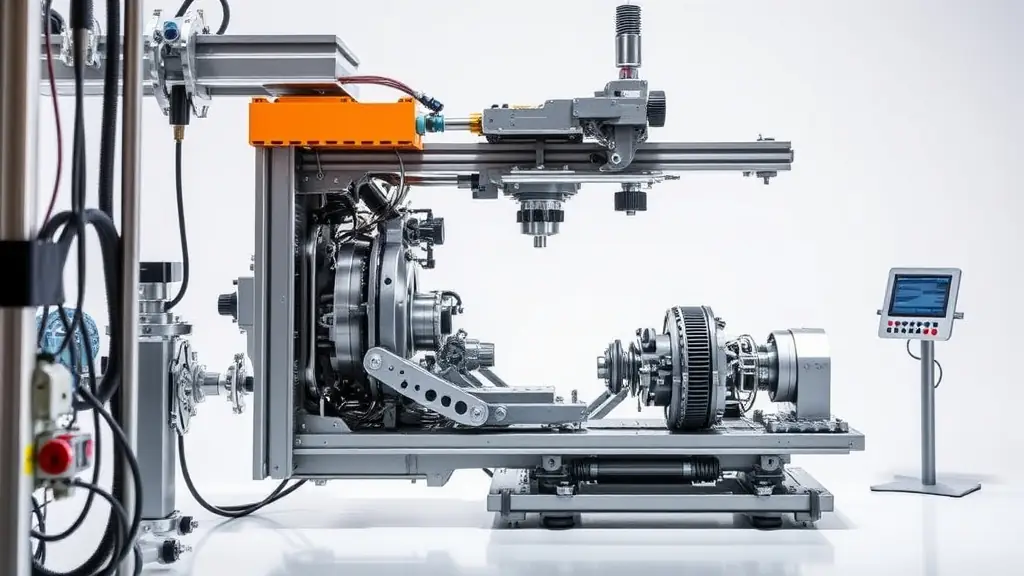

Clamping Systems

Cutting Optimization

Our Expertise in Mechanical Processing

Experience in machining with chip removal, as well as being the Specialist, with over 30 years of experience, in machining on sintered workpieces, both with standard hardness characteristics and sinter tempered.

Study, Design and Realization part gripping. Study and Research reliable and competitive machining partners. Study and Research of Optimal Cutting Technology.

Analysis and Optimization of the tool path strategy that will allow us to optimize the machining cycle.

Technical Assistance, Training and Consulting for the optimization of existing production processes

Study and Design piece taking with 3D presentation, with analysis and study of Time and Methods

• Specialist in Sinter Parts and beyond

• Workpiece pick-up on machine tool

• Workpiece gripping for part manipulation with both cobot and gantry robots

• Study and Design of Robotic Areas. Re-design of existing robotic areas.

• Study and Research of the technologies best suited to the Customer’s production needs (both as workpiece gripping equipment and machine tools and as technological change for chip removal)

Turn-key management

• Project Management and Installation with execution of the first Step-Up parts: machine tool and equipment

• Analysis and Compilation of program for CNC, Fanuc ISO and/or Parametric language

Training courses for ISO/Fanuc and Parametric programming (…with brief mentions for reading technical drawing)

Research and Selection of the best cutting solutions to increase productivity and/or give greater

stability to the production process

Search and Selection Reliable and compective production partners according to the customer’s required needs

Research and Selection of new technologies for both production and in-process part inspection (in-process dimensional inspection)

Consulting in the Development, Upgrading, Implementation of Quality Management Systems (QMS) from an Automotive IATF 16949 perspective with dedicated tools or from an ISO9000 perspective

Testimonianze dei Nostri Clienti

Testimonianze dei Nostri Clienti

Testimonianze dei Nostri Clienti

Client Testimonials

Project Manager, Client A

Operations Director, Client D

Technical Lead, Client G

Client Testimonials

Project Manager, Client A

Operations Director, Client D

Technical Lead, Client G

Client Testimonials

Project Manager, Client A

Operations Director, Client D

Technical Lead, Client G

Building Strong Mechanical Partnerships

Our Success

Real-World Impact

Project Highlights

- Client: Automotive Manufacturer Inc.

- Date: May 2023

- Outcome: Significant efficiency gains

More Success Stories

- Client: Aerospace Solutions Ltd.

- Date: November 2022

- Outcome: 20% reduction in machining time

Client Testimonials